.jpg)

Presentation

Research

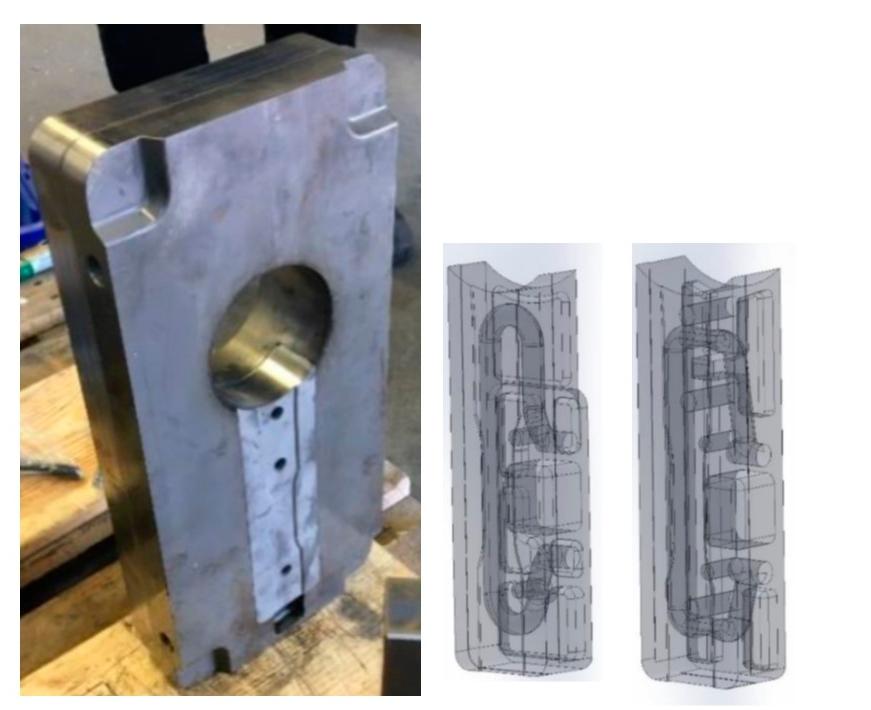

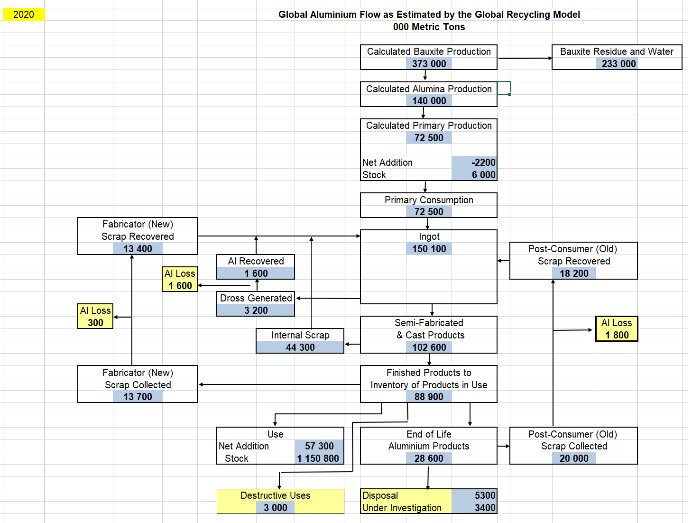

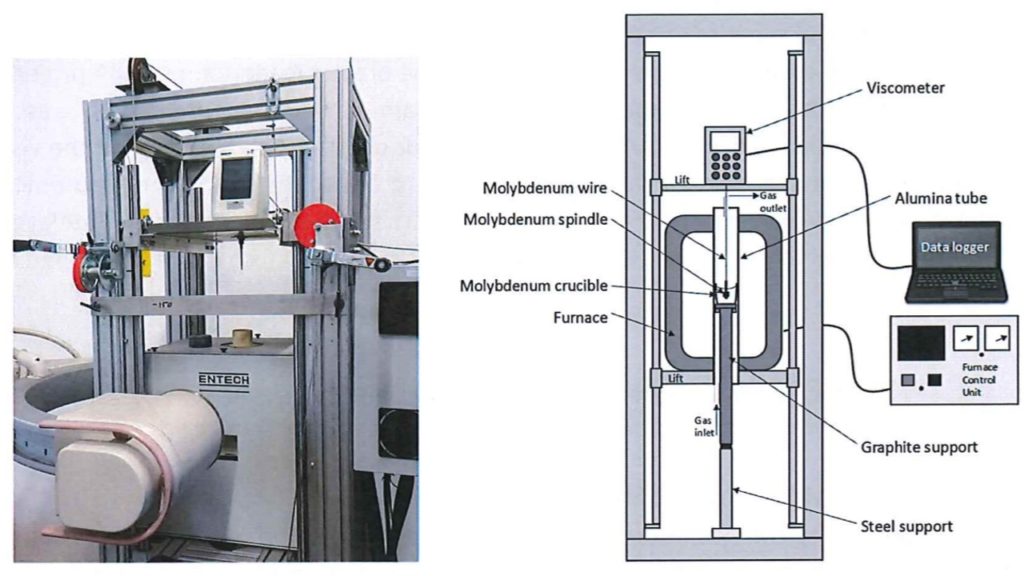

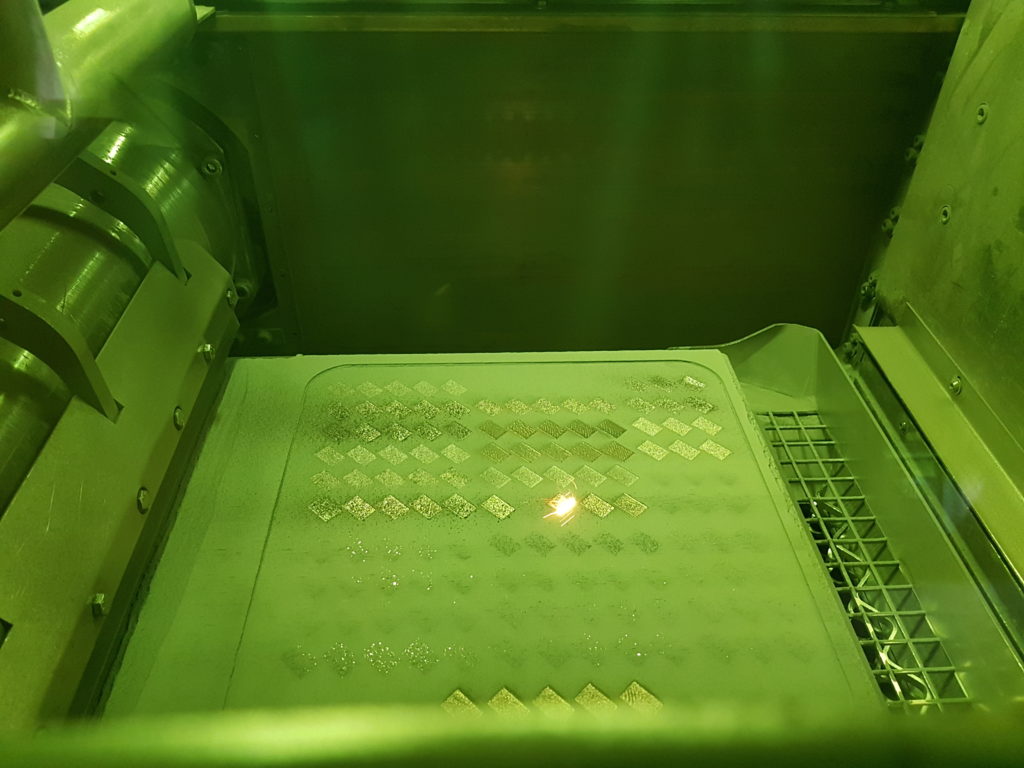

The research area includes technology for the manufacture of cast components, both the process chain as they finished their structure and properties, as well as phenomena that are of importance for its quality.

Of particular interest is to create opportunity for the effective use of modelling and simulation in the various parts of the manufacturing chain from melt to finished component. Particular focus is on material properties during the manufacturing process, and the finished component. Sustainable development is an important element for component manufacture in which particular focus is on design criteria to maximize use of local material properties, as well as high process yields, and through the optimization of materials, process path and selection of process parameter for defect free castings.

Current on-going research includes

Alloy and process development for manufacturing of high performance components for telecom applications.

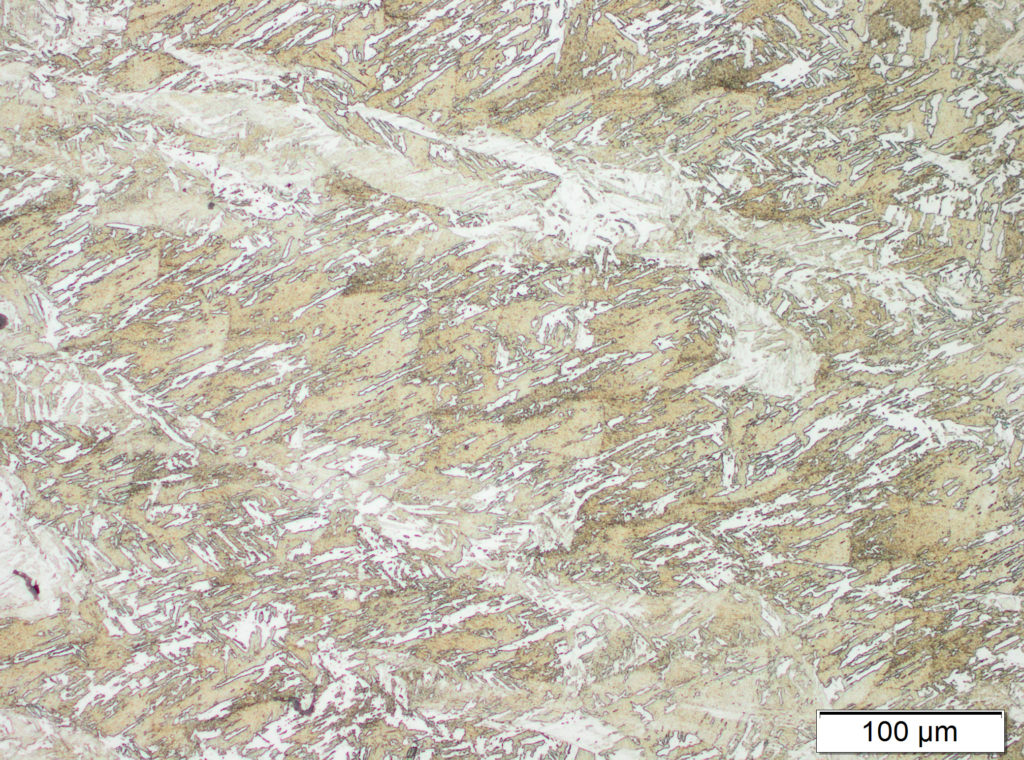

Ultra high strength Mg-based alloys.

Teaching

Anders Jarfors has been examiner and lecturer in several courses in Bachelor, Master and Doctorate Education at KTH (Royal Institute of Technology, Stockholm). He has been teaching courses in Materials Science, Casting and Manufacturing. He is the author of two books, one in Manufacturing Technology and one in Simulation and Modelling in materials Processing.

Biography

Born in 1963 in Trollhättan, Sweden Anders Jarfors is, with his resent move to Jönköping, almost back where it all started! Anders Jarfors has a MSc, and PhD from KTH (Royal Institute of Technology, Stockholm). In 1990 he was awarded the Young Scientist Award by the European Materials Research Society and in 2000 he was given the title Docent (Associate professor (US) / reader (UK)).

2000 was an eventful year as he left KTH for Gintic Institute of Manufacturing Technology, Singapore, as a Senior Research Fellow. The institute was later reorganized and I continued as a Senior Scientist at the Singapore Institute of Manufacturing Technology (SIMTech).

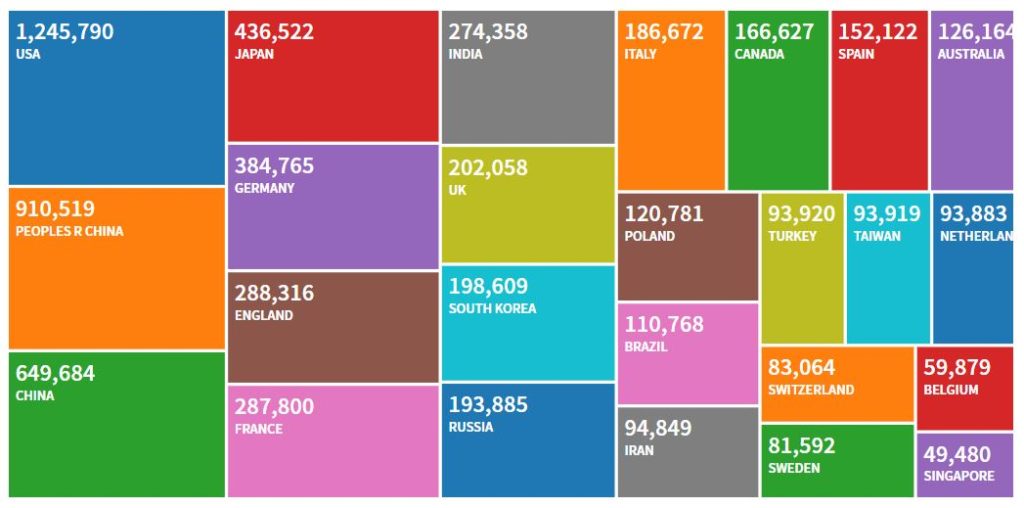

The work at SIMTech was mainly process trouble shooting for the contract manufacturing industry in Singapore and Malaysia, supporting manufacturing of products for telecom, disk drives and automotive applications. In 2003 he was seconded on 80% to MMI Holdings as Senior Engineer and acting Head of Engineering to manage the engineering part of the transfer of a whole factory from USA to Singapore. The remaining 20% was spent supervising students developing biomaterials and biocompatible coatings.

In 2004 it was time to move again were Anders Jarfors became Head of Alloying Technology Department and later Business Area Director at the Corrosion and Metals Research Institute (KIMAB) in Stockholm, Sweden. He was responsible for activities in Casting and Solidification, Powder Metallurgy, Computational Thermodynamics, Thermo Mechanical Processing, Metallography and Analytical Chemistry. The research work performed was pure contract research, mainly concerning material development and process development for the Swedish metallurgical industry, including steel and powder metallurgical activities, with clients being the major Swedish steel producers.

In 2007 Anders Jarfors returned to Singapore Institute of Manufacturing Technology as a senior scientist and was the technical manager for the SERC Aerospace Programme. Concurrently he also acted as an expert consultant for the Precision Engineering Centre of Innovation in the aerospace sector and in heat treatment. The main research work however was related to casting with work focusing on automotive components, electronics cooling and domestic appliances.

Anders Jarfors was also appointed Adjunct Associate Professor with School of Mechanical and Aerospace Engineering at Nanyang Technological University. Here the research focused on sheet metal forming as superplastic forming and microstamping. A large research grant to develop ultra-high strength Mg based metallic glasses was also won which is still on-going.