Experimental Foundry

In our small foundry called JUcast we cast iron, steel, aluminium and magnesium alloys.

Being able to perform casting experiments on-site is very beneficial to our research. It allows us for example to experiment with new alloys and casting techniques, and to investigate how the casting process parameters influence microstructure and macroscopic properties.

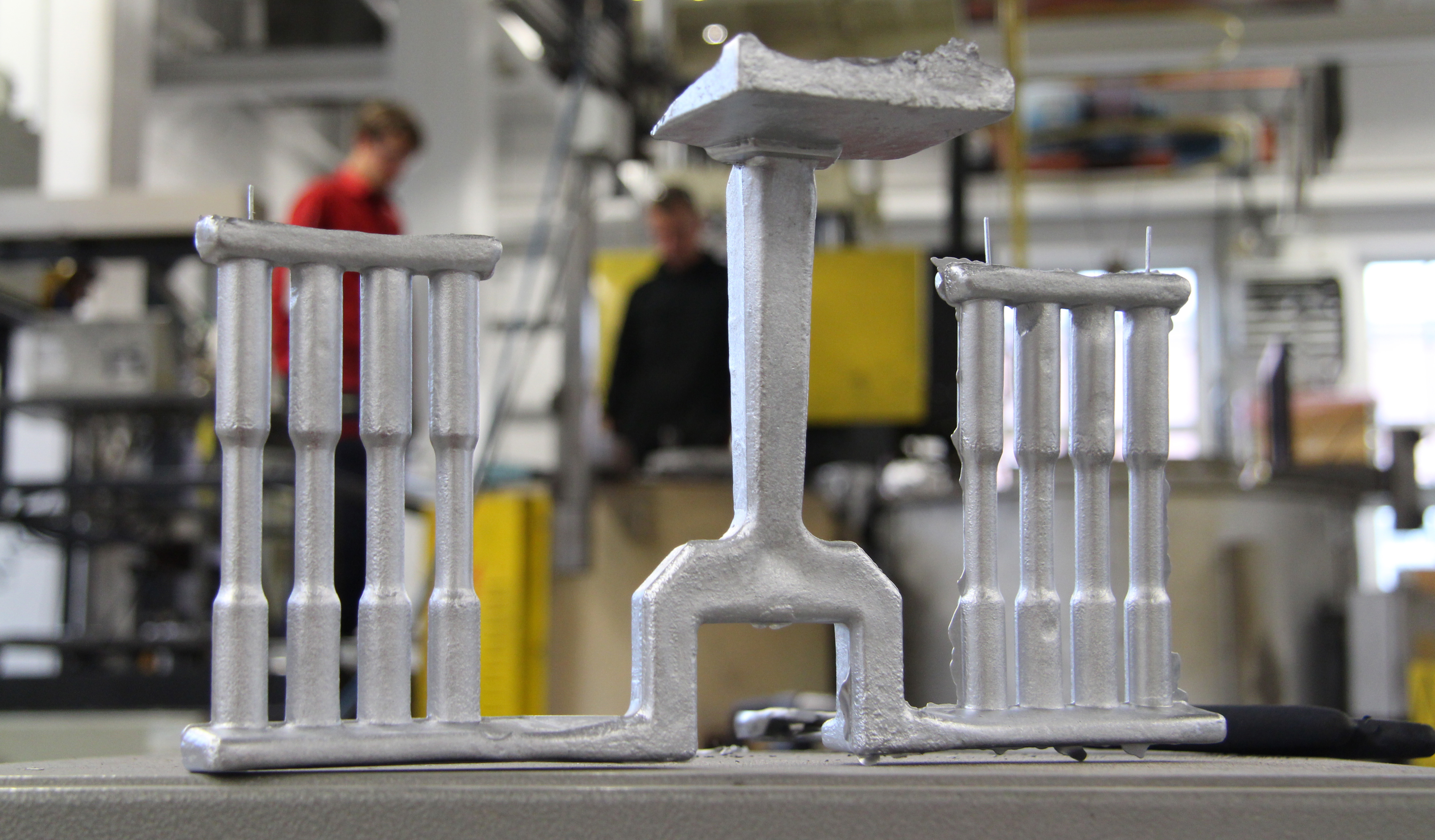

High Pressure Die Casting

High pressure die casting is a technique widely used in the industry, and having our own high pressure die casting machine allows us to apply our theories in practice. We use it for producing test specimen of various conventional and experimental alloys, as well as for research on semisolid casting.

Sand Mould Casting

As part of our research on cast iron we conduct sandcasting experiments with different process parameters and alloys. Sandcasting makes it convenient to study the effects of different mould geometries.

Tilt Casting

In our foundry we have a machine for tilt pour casting of aluminium alloys, which allows for a well-controlled and continuous fill rate. This technique minimises turbulence during filling and in turn the presence of oxides inside the component.

X-Ray Furnace

The solidification process and the following phase transitions set the microstructure and have a significant impact on the components’ mechanical properties. With our x-ray furnace we can study the solidification process in real time for iron, steel and aluminium alloys.