CHROME SURF-Crome and “Chrome look” Automotive interior surfaces

Facts

Academic Partner: Tekniska Högskolan

Industrial Parnters:

P.O.P, Plating on Plastics AB

Duration of the Project: 2018-2021

Research team:

B.-G. Rosén, Co-manager

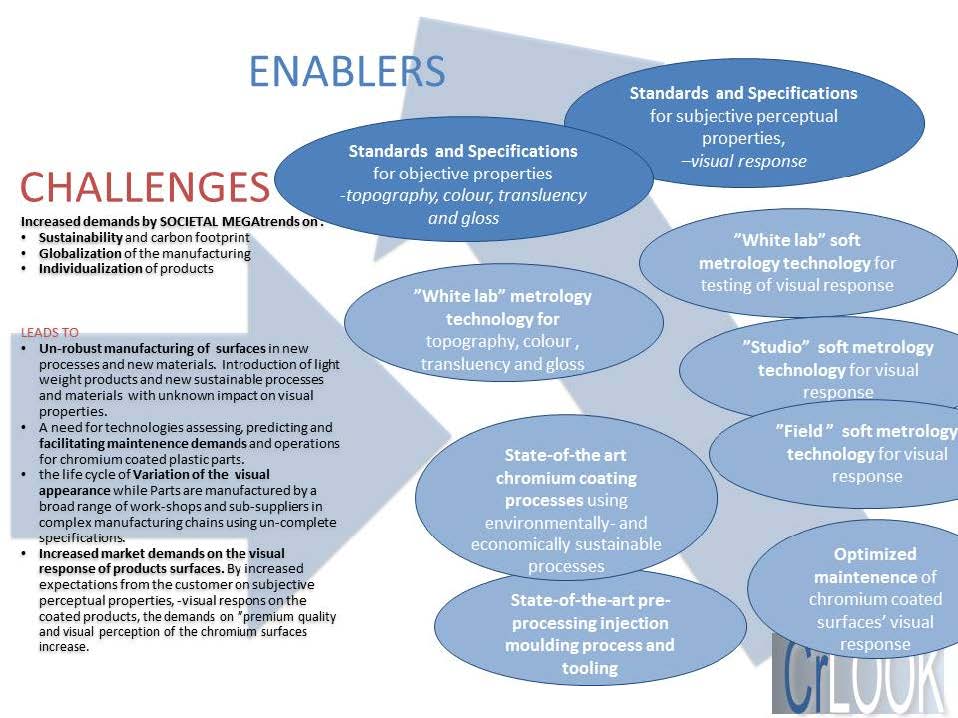

Increased demands on industry by societal megatrends on Sustainability, and

decreased carbon foot print, Globalisation of the manufacturing and the increased

demands of individualized products leads to an industrial climate of constant

development and improvements and the interior design of cars and trucks are not excluded.

This project aims at introducing a set of “enablers” capable of supporting the development of automotive interior “chrome look” surfaces on components made by new concepts of improved injection moulding processes, new sustainable plastic materials.

Introduction

Metal parts and metal surfaces have been extensively in use for automotive interiors since

the early days of motorism but during the last decades environmental demands on

decreased fuel consumption, and environmentally greener and safer manufacturing

processes has led to an increased use of lighter and less carbon foot print plastic interior

parts with plated or painted metal surfaces.

The metal plating products are manufactured by injection moulding and plating and material variables influence significantly the appearance output. The manufacturing processes for generating those highly complex surfaces are therefore decisive in terms of the technical as well as the economic performance of the product.

Purpose

The functionalization of surfaces is an important step for bringing special properties onto

technical products. Typical features are glossy metal surfaces for car interiors where gloss,

colour and texture patterns heavily influence the total appearance.

The current trends and developments leads to the introduction of new more- or less tested concepts of “shiny” interior parts, based on new materials and processes simultaneously as the customer in many cases and market segments demand a higher quality. The higher quality is not only expressed in terms of glossiness and colour of chrome- or chrome look interior parts but also of the visual variation and balance between nearby or associated parts in the interior.

Controllable injection moulding- and coating processes result in predictable gloss and colour levels but needs to be completed with a matching quality system ensuring the glossiness and colour over time and that surfaces perceived as the “right” and expected quality by the end-user, -the customer.

Expected result

To meet the aims of the project, focus is to develop a quality system with surface

specifications ensuring the level and controllability of the visual perception of the chromium or chromium like surfaces. This will be made in close interaction with state-of-the-art chromium plating and injection moulding processing.

The project will develop standards and specifications for the objective surface properties like opography, colour, translucency and gloss as well as subjective perceptual properties, -the visual customer response. The development of the standards and specifications as

“main” enablers towards the project aim is based on enabling technologies to be developed and implemented in the fields of: “white lab” metrology of topography, colour, gloss and translucency, processes for chromium coating and injection moulding, “white lab-”, “studio-“, and “field-“ metrology of human visual perception as well as maintenance technology to ensure the durability and life time of the chrome coated surfaces (see fig below).

More information:

Financier

Do you want to know more about this project?

Do you want to develop the next project with us?

- External Relations Manager

- School of Engineering

- linda.bergqvist@ju.se

- +46 36-10 1074