Development and Analysis of Automated Data Collection Solutions for Tool Maintenance in CNC Machines

Production Development and Management

Ioana Andreea Cocis

LinkedIn Länk till annan webbplats, öppnas i nytt fönster.

Cezar Adrian Stefan

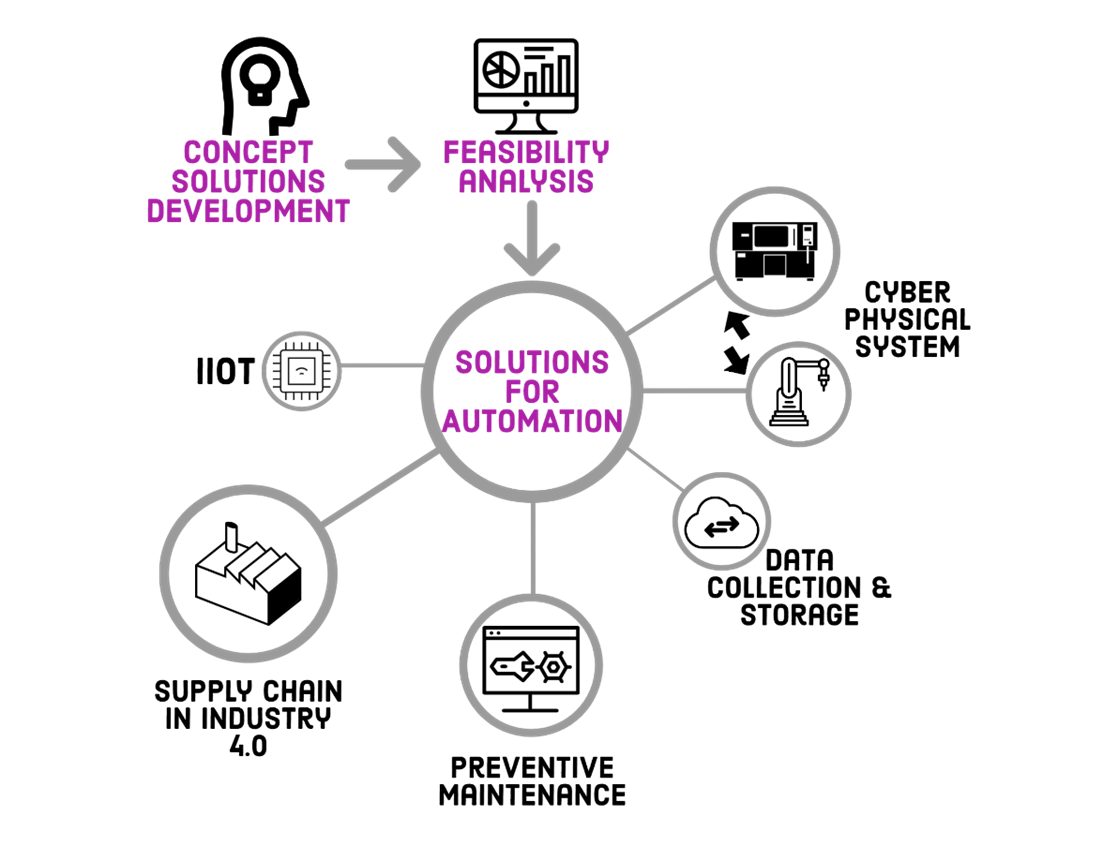

The constant awareness on CNC tools health represents a critical standpoint towards developing smart factories as it enables high productivity and high-quality goods. Thus, we are aiming towards the development and analysis of automated data collection solutions for SMEs.

Since small-to-medium enterprises (SMEs) represent a backbone for sustainable economic growth, the need for increasing the degree of automation in production plants is pushing today’s engineers to find customized and cost-efficient solutions. In the Industry 4.0 context, SMEs which are aspiring towards quality, competitiveness and overall customer satisfaction require to work with a systematic approach for implementing cyber physical systems (CPS) that are functioning autonomously and independently from human interaction. An essential area within manufacturing is represented by the maintenance of CNC machine’s tools that are directly responsible for achieving high-quality products. Since corrective maintenance is associated with uncertainty, unforeseen costs and increased downtime, the focus is diverted towards uprising trends of preventive and predictive maintenance policies. The purpose of this thesis is to increase knowledge in the field of new maintenance practices in the context of Industry 4.0 and to provide a framework for achieving customizable automated solutions adapted for the needs and requirements of each individual SME. Our guideline is following to transform the needs of SMEs into technical specifications which are used for designing and generating conceptual solutions whose effect is assessed from technical, economic, socio-environmental, operational and schedule perspective. Furthermore, this framework is conceived to offer a long-term holistic view of the future changes resulted by the implementation of automated solutions.